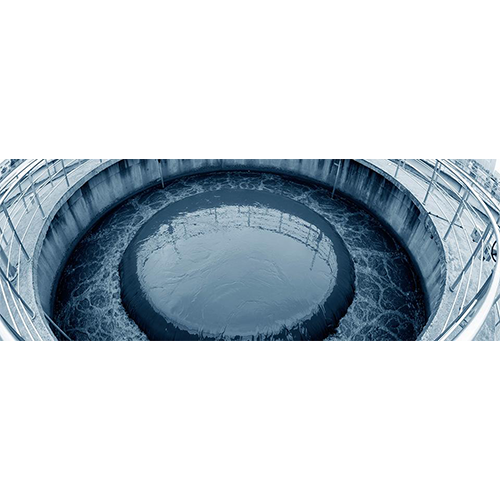

About HERPASA STAINLESS STEEL TANKS

HERPASA He began his business in the early 60's. The main factory is located in Barcelona (Spain) and has a surface area 8.000 m2.

We specialize in stainless steel Boilers, we manufacture high capacity tanks and silos of high quality. We have a commercial, Technical and Operations team with extensive experience in the field of stainless steel boiler equipment..

HERPASA is leading manufacturer of stainless steel tanks with a presence in the largest and most well-known companies. We have manufactured stainless steel tanks for over 45 years.

We use state-of-the art machinery , to ensure the tank has the highest quality finish. We have Own Engineering Department, allowing us to make turnkey projects. As far as software is concerned, we have AUTOCAD, from AUTODESK, the basic software that we apply to all our project designs, and which is constantly updated. Our work focuses on customer service..

Herpasa was awarded the initial certification of quality, that complies with the 2000 version International Quality Standard UNE-EN-ISO-9001 2000, and later re-certified and updated to the 2008 version after the audit conducted by 2008; Bureau Veritas Bureau Veritas. It has a factory equipped with the most modern machinery and the most refined technique for the continuous production of stainless steel tanks.

- The extreme quality and perfection of welding, performed automatically with full penetration, adapting a special welding procedure in an inert atmosphere, distinguishes us from the competition.

- Certified welding 5 machines with 5 proprietary welding procedures, based on the GTAW TIG welding technique.

- Electric arc welding procedure with refractory electrode in a gaseous atmosphere.

- El inert gas, usually based on Argon, insulates the molten metal, the hot spots and the tungsten electrode, thus avoiding any oxidation. Under the protection of the inert gas, an electrical arc between the non-consumable tungsten electrode and the work piece is necessary.

- Cooling jacket construction system for application to the tanks and to achieve the maintenance of a constant temperature of the product stored inside the tank.

- Robotic roller welding system to prevent overheating of the stainless steel sheet and achieve a reliable bond guaranteed to be watertight.

BRANDS

Response rate -

Not Calculated

Response rate -

Not Calculated

Response time -

Not Calculated

Response time -

Not Calculated

Number of Products 7

Number of Products 7